Your Trusted Hydraulic Bolting Solutions for the Oil & Gas Industry

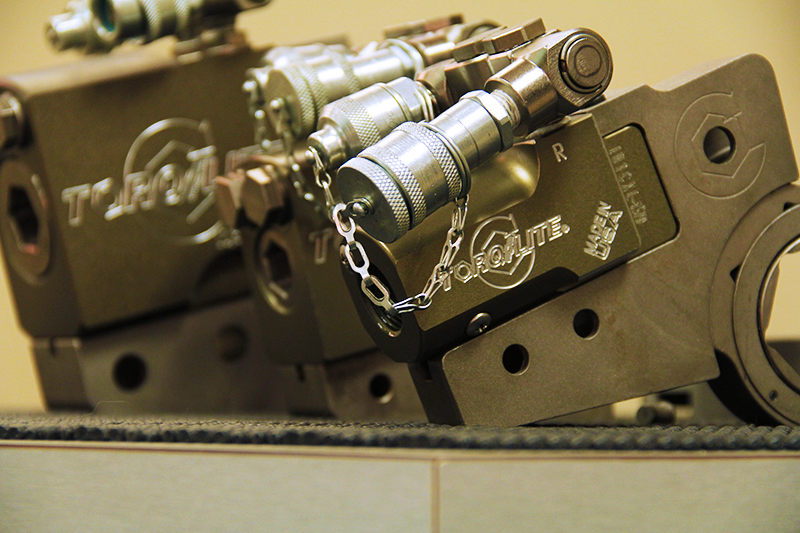

For over 40 years, TorqLite has provided reliable hydraulic bolting solutions, helping improve safety, efficiency, and performance in the oil and gas industry.

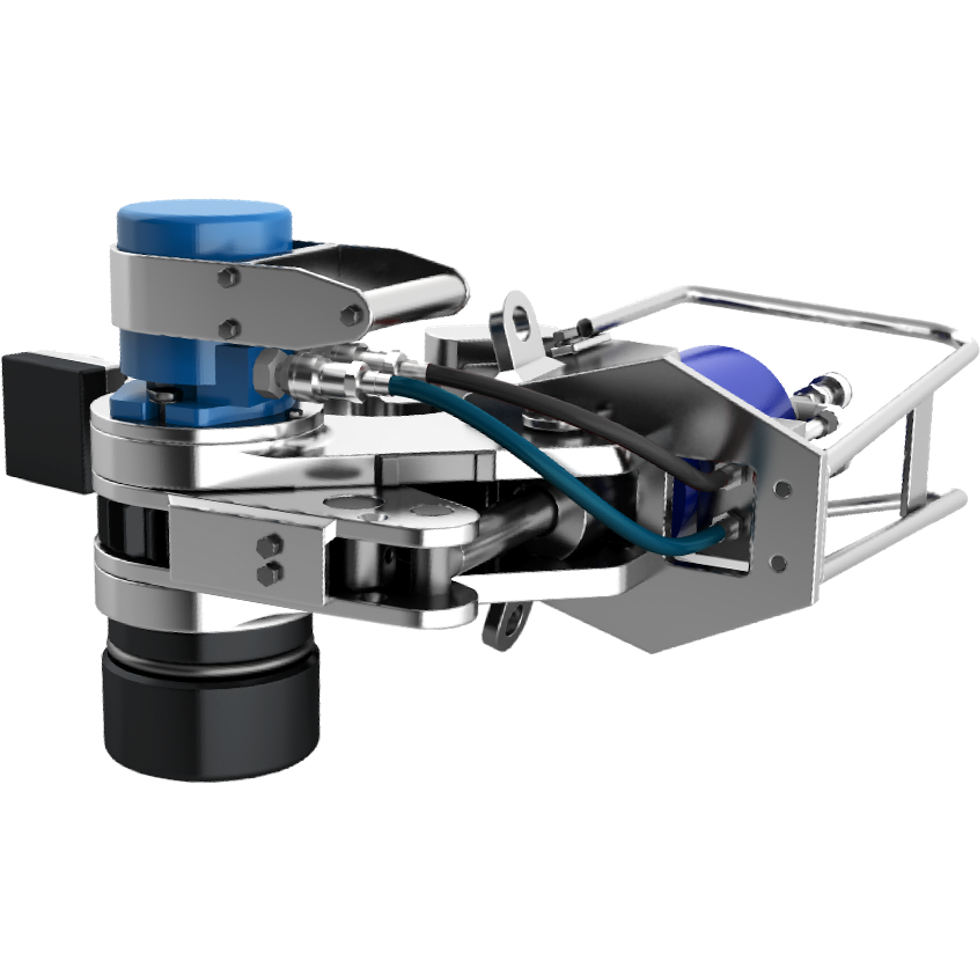

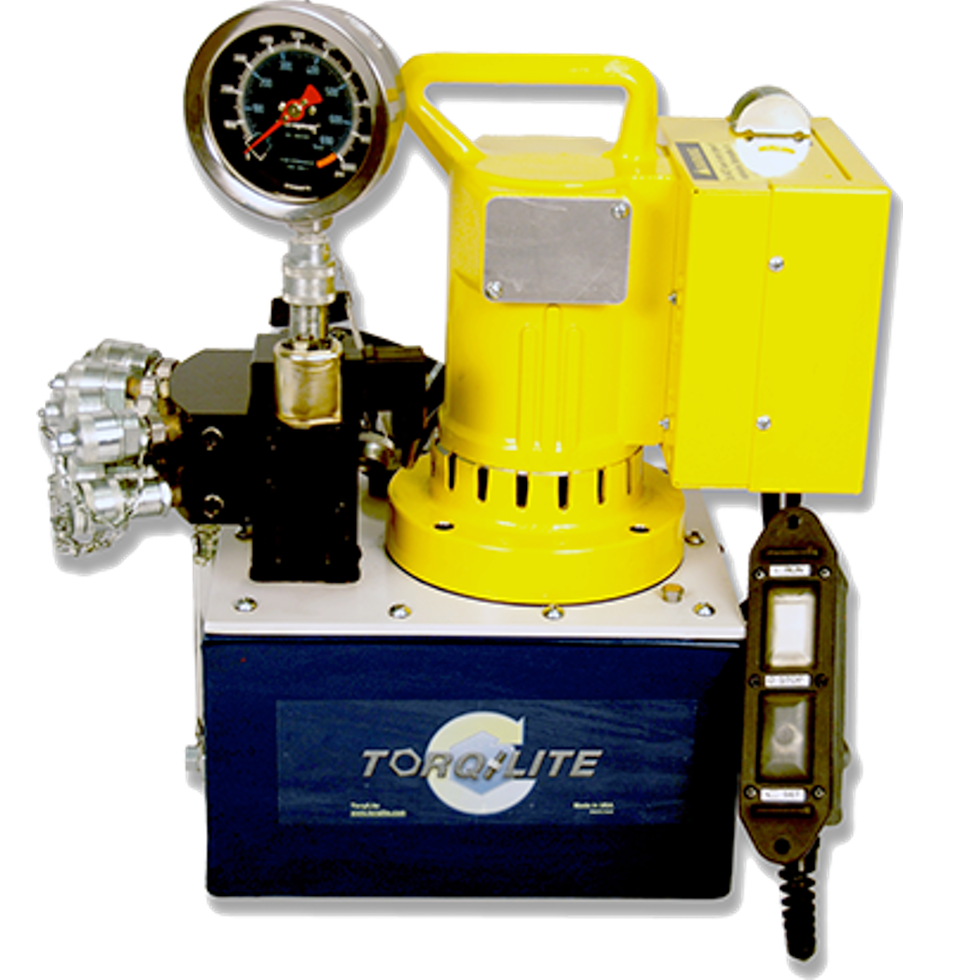

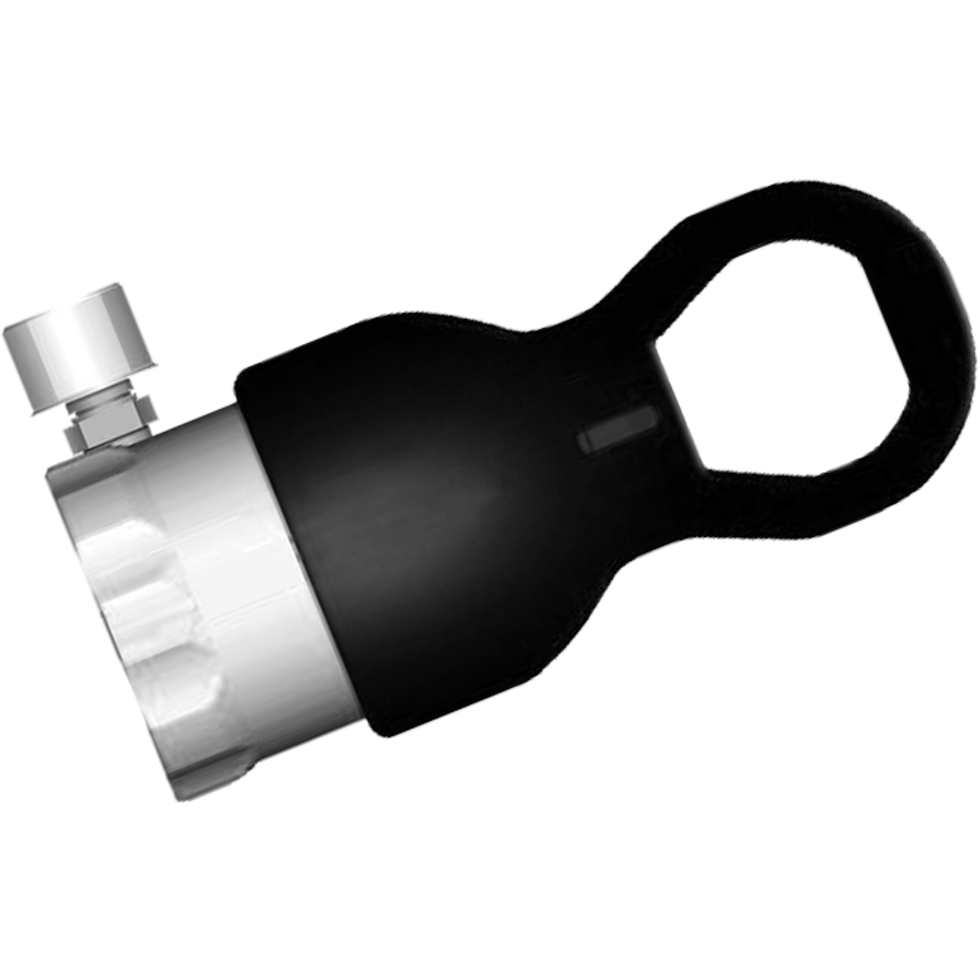

Why Choose TorqLite High-Quality Hydraulic Torque Wrenches?

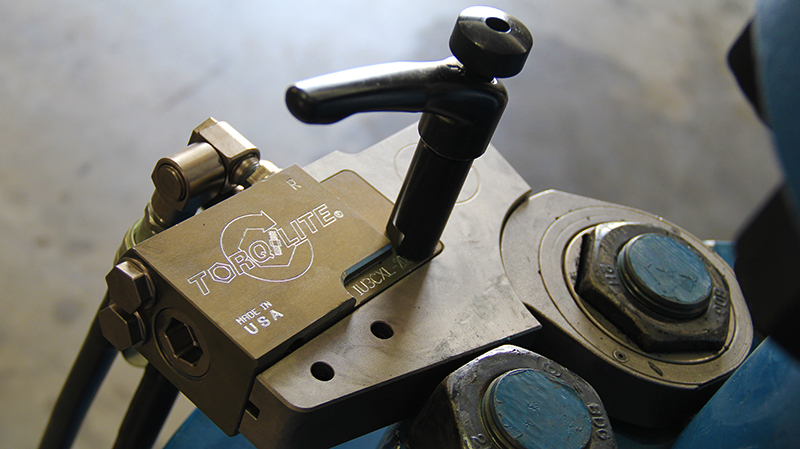

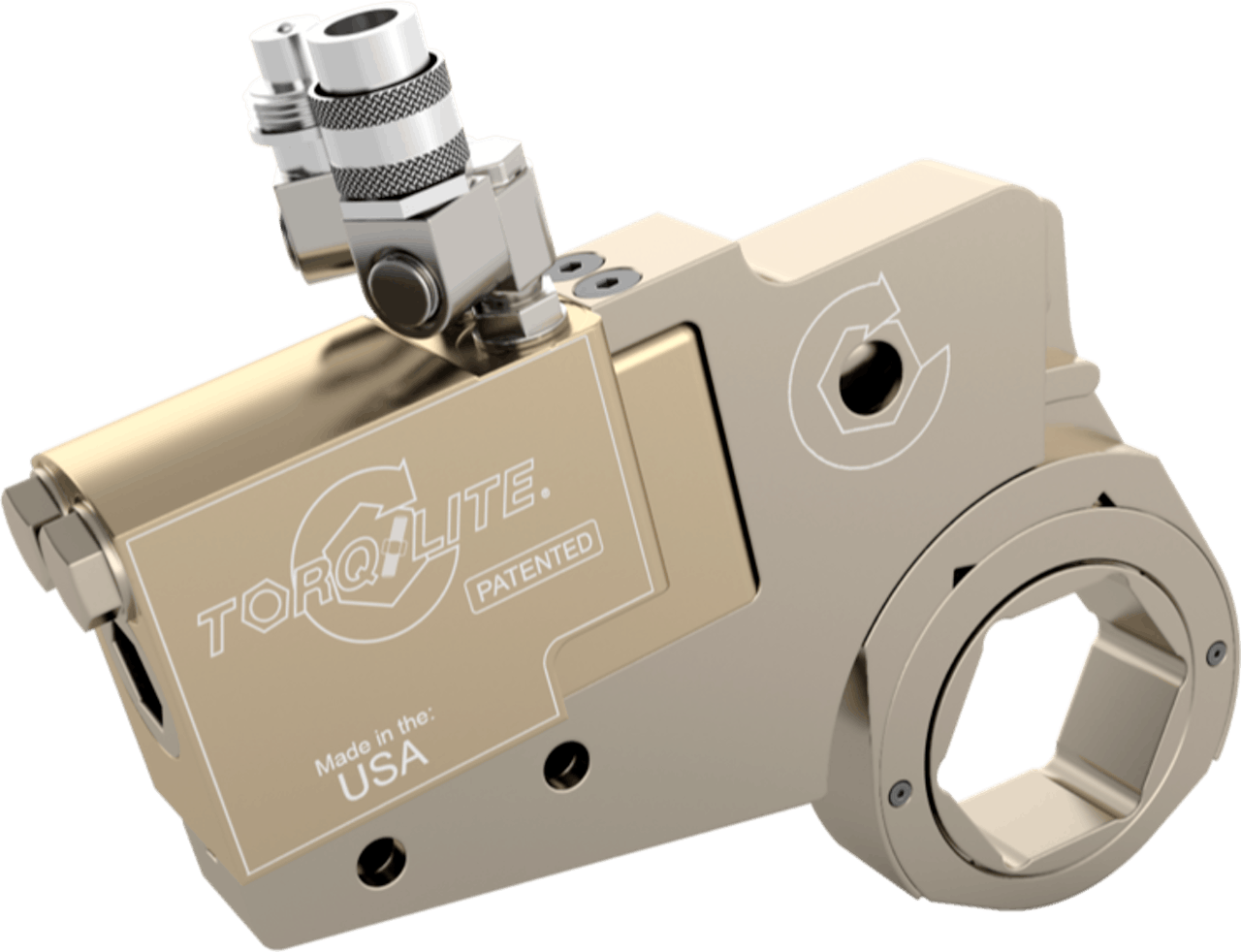

TorqLite’s commitment to engineering excellence ensures that every tool we design, manufacture, assemble, and test in our U.S. facility delivers precision, durability, and efficiency in high-stakes bolting applications. With decades of expertise, we continue to innovate, offering industry-leading solutions tailored to the most demanding projects.

As an ISO 9001-certified manufacturer, we uphold the highest quality and performance standards for our products and services. Whether for standard or custom applications, our high-quality hydraulic torque wrenches enhance safety, optimize performance, and help you tackle even the toughest bolting challenges.

TorqLite is one of the world's preeminent manufacturers & suppliers of high quality hydraulic torque wrenches & bolting solutions to the oil & gas industry.

Given TorqLite's origin story, it is understandable that our company is a leader in providing bolting solutions to the Oil & Gas industry. More than 40 years ago, our products began regionally servicing the Gulf of Mexico, and since then, we've designed and launched several tools to our arsenal that greatly improve a wide variety of Oil & Gas applications.

Here are just a handful of our Oil & Gas customers.

Innovation sets TorqLite apart from competition and allows us to effectively serve our customers.

We provide customers support for ongoing projects, and help them tackle their most pressing bolting challenges. We offer needed equipment solutions and know-how to handle any job… no matter the size or complexity, we have the right bolting solution or we’ll invent it. If you need a tool but don’t see one that fits your particular needs, contact us today and we’ll help you find a solution that works for you.

Essential Hydraulic Bolting Solutions for the Oil & Gas Industry

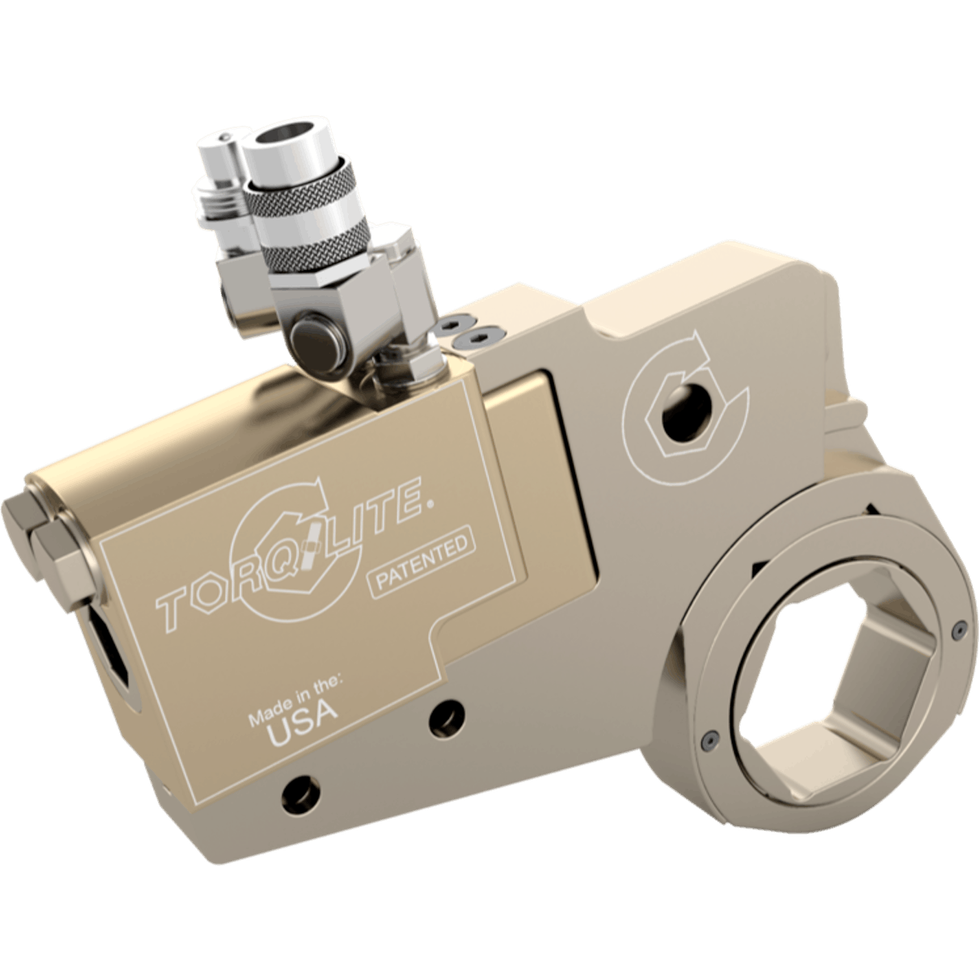

Unmatched Accuracy

Achieve precise and uniform bolt tightening with TorqLite’s high-quality hydraulic torque wrenches designed for critical oil and gas applications. Our tools minimize human error, ensuring consistent and dependable operation in risk-intensive environments.

Optimized Safety

Reduce workplace hazards with advanced bolting solutions that eliminate manual strain and enhance operator protection. Designed for high-pressure settings, our tools help prevent injuries and ensure compliance with industry safety standards.

Heavy-Duty Performance

Our hydraulic tools are built to withstand extreme conditions and deliver exceptional offshore and onshore operations performance. Engineered for durability and reliability, they easily withstand high pressure, corrosive environments, and challenging workloads.

Broad Compatibility

From pipeline maintenance to pressure vessel assembly, our hydraulic bolting solutions seamlessly integrate into various oil and gas applications. With a wide range of torque capacities and tool configurations, we provide the right fit for every job.

Expert Support & Service

Access industry-leading technical support, training, and after-sales service to keep your projects running efficiently. Our team of experts is always ready to assist, ensuring you get the most out of your hydraulic bolting tools.

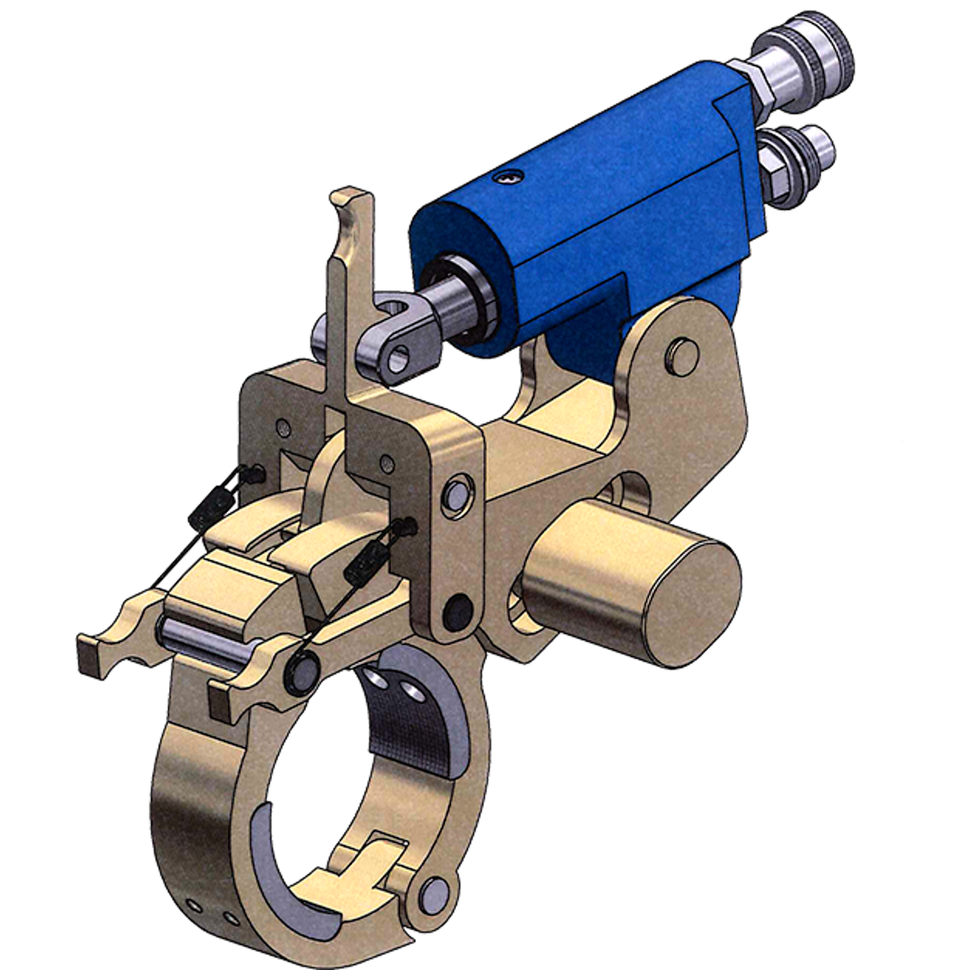

Oil & Gas Hydraulic Tensioning Applications

TorqLite equips you with specialized products that tackle everything from nipple-up tasks to deepwater offshore operations, ensuring precision, efficiency, and consistency for industry-specific challenges. Our high-quality hydraulic torque wrenches and tensioners are perfect for:

- Turbine engine rotors

- Industrial process reactors

- Thermal transfer units

- Power generation units

- Pipe connection flanges

- High-torque shaft couplings

- Heavy-lifting equipment

- Structural anchor bolts

- Flow control systems

- High-pressure containment tanks

- Gas turbine and compressor assembly joints

We are an ISO 9001 Certified company, dedicated to producing the highest quality products.

Our quality hydraulic torque wrenches are designed, manufactured, assembled, and tested in our U.S. facility. Our quality control ensures that our customers only receive exceptional tools.

Expand Your Business with TorqLite’s WRSC & Distributor Programs

Looking to scale your business with trusted tools and industry support? TorqLite is offering opportunities to become a Warrantied Repair Service Center (WRSC) or an Authorized Hydraulic Tools Distributor. WRSC partners are certified to repair TorqLite tools under warranty, gaining access to free parts, specialized training, and labor reimbursement. As a distributor, you'll be equipped to sell our high-performance bolting solutions with expert training and marketing support.

Joining is easy—just reach out to TorqLite, and we’ll provide all the details on qualifications, training, and benefits