Our innovative, low-clearance wrench can fit just about anywhere, a perfect tool for every job.

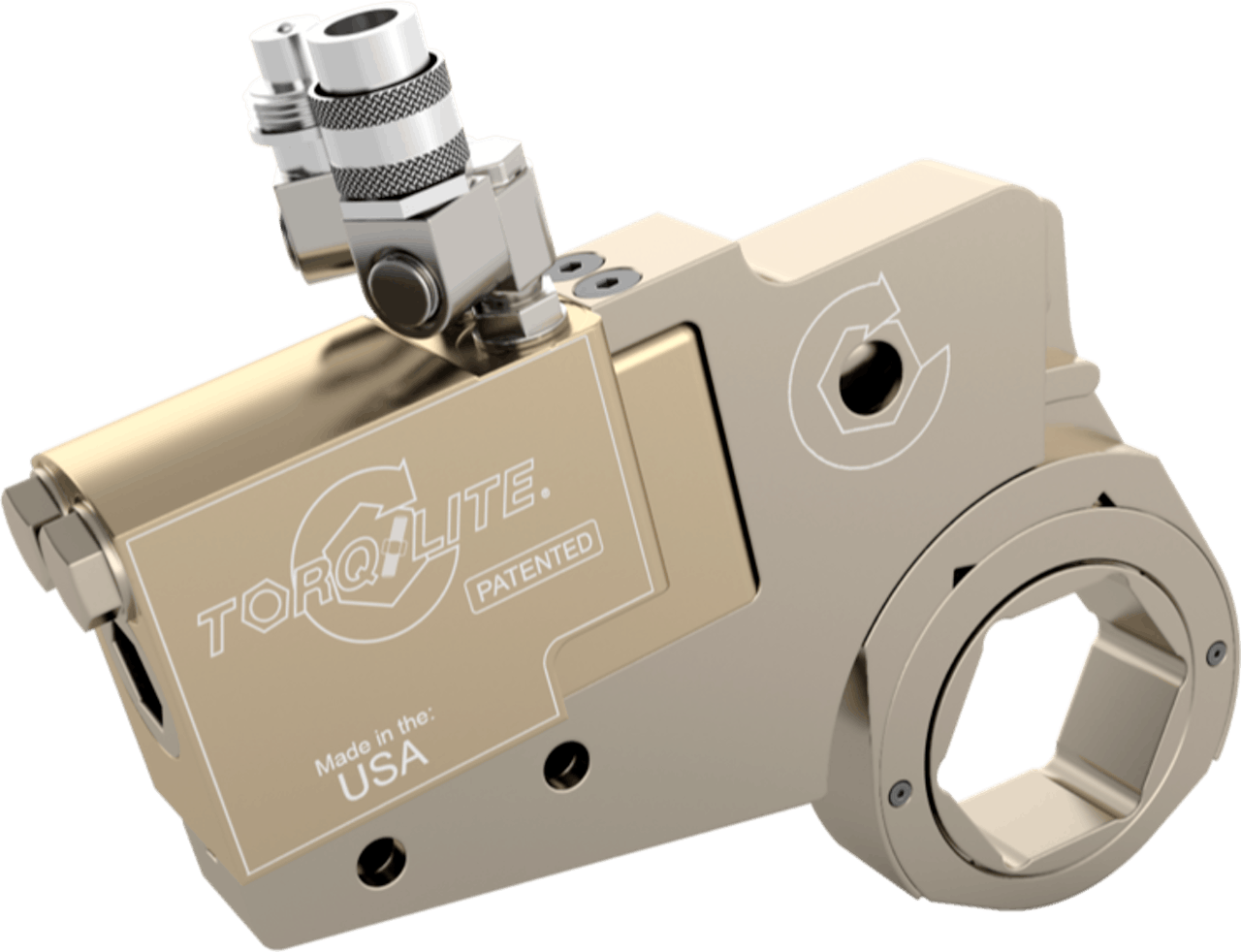

The patented inline-ratcheting design combines the cylinder and the body together in one unit, so changing the head is all that's required when switching sizes. This gives you the ability to use one body & cylinder unit for a wider range of nut sizes, simplifying your operation and saving you money.

Our wrench is versatile, durable, and all that you need to get the job done.

IU-XL Series (Low Clearance)

The ultimate Low-Clearance Wrench product.

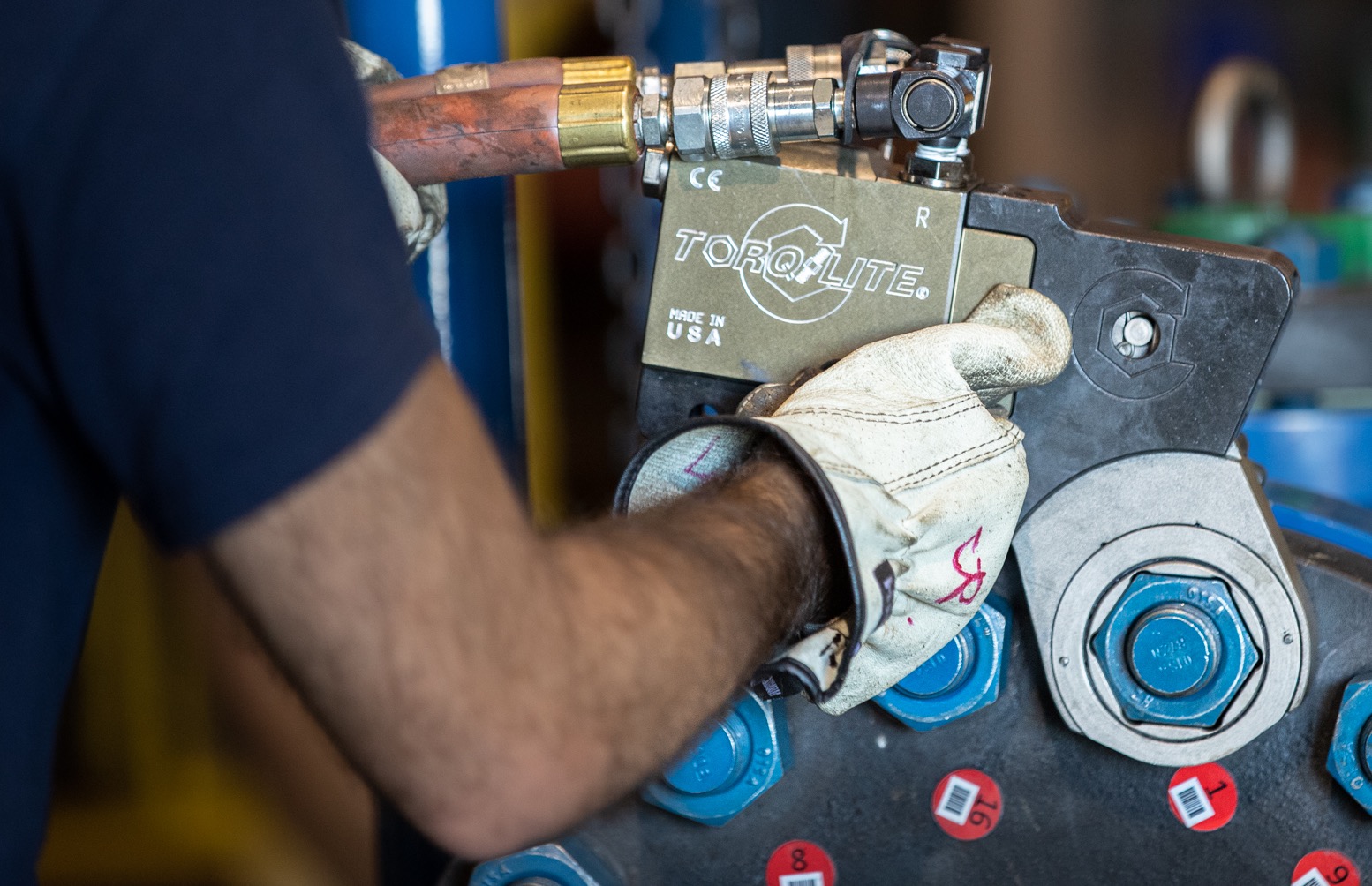

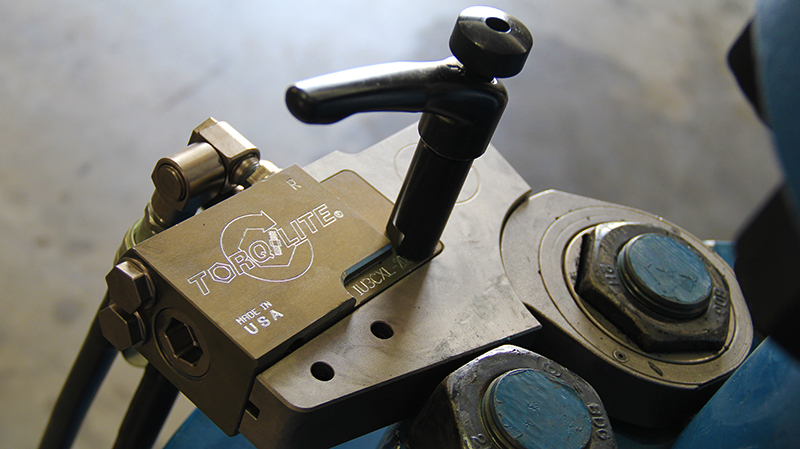

- Practical Body Design This low-clearance industrial torque wrench is designed with a super-low profile ensuring that it can fit just about anywhere.

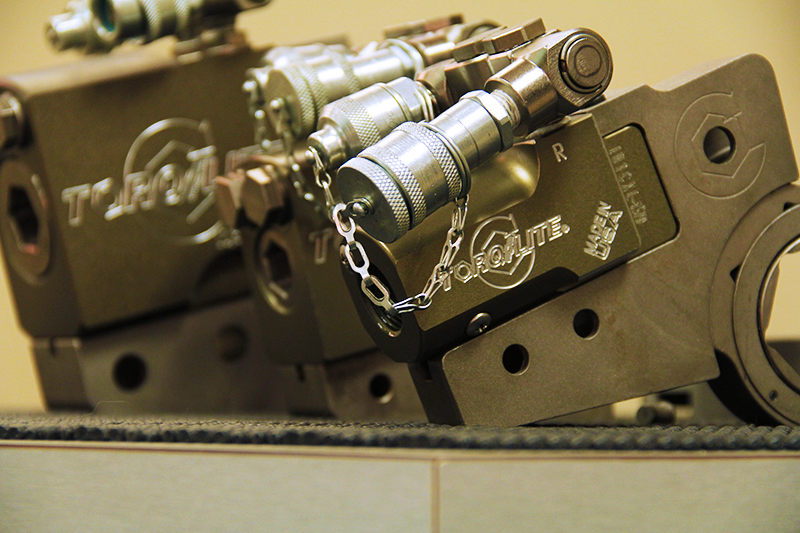

- Full rotation swivels Our patented 360º swivels rotate on both axes, giving you enhanced control and maneuverability.

- Superior functionality The cylinder and the body are together in one unit, so changing the head is all that's required when switching sizes.

A powerful, effective pump is needed for these tools. See our pump selection to find the right pump for you.

Patented Low-Clearance Hydraulic Torque Wrench

The IU-XL Series torque wrench features a patented low-clearance design, making it the ideal tool for tight spaces and challenging jobs. This innovative design allows you to tackle tasks that would otherwise be impossible with traditional wrenches, offering unmatched flexibility and precision.

Its unique inline-ratcheting mechanism combines the cylinder and body into a single unit, allowing you to switch sizes with ease—just change the head. The IU-XL Series low-profile hydraulic torque wrench helps you save time, reduce costs, and streamline your operations, giving you the power to handle a broader range of nut sizes with one efficient tool.

Practical Body Design

This low-clearance industrial torque wrench features a super-low profile, allowing it to fit into tight spaces easily.

Full Rotation Swivels

Our patented 360º swivels rotate on both axes, providing superior control and effortless maneuverability in any direction.

Superior Functionality

The cylinder and body are combined in one unit, allowing easy head change-outs for quick and effortless size-switching.

Why Choose TorqLite as Your Hydraulic Bolting Partner?

TorqLite is the industry leader in hydraulic bolting solutions and is trusted globally for its high-quality torque wrenches and bolting systems. With over 40 years of engineering excellence and more than 20+ patented tools, we’ve pioneered groundbreaking solutions by listening to our customers and solving real-world bolting challenges. TorqLite IU-XL Series are made in the U.S.A., using quality materials and the highest quality manufacturing standards. Choose TorqLite for unmatched innovation, reliability, and performance, ensuring your projects are completed with precision and efficiency.

Explore Other TorqLite Hydraulic Bolting Solutions

Explore Our Quality Distributed Products

Interested In Becoming a TorqLite Authorized Hydraulic Tools Distributor?

Unlock new business opportunities by partnering with TorqLite as a Warrantied Repair Service Center (WRSC) or an authorized distributor.

WRSCs gain access to warranty repair work, exclusive discounts on parts, and labor reimbursement, while distributors benefit from product training, marketing materials, and potential sales exclusivity. Both programs are designed to help you grow your business and establish a strong presence in the hydraulic bolting industry.

Getting started is simple—just fill out the form, and our team will guide you through the requirements and training necessary to qualify.

Low Profile Torque Wrench FAQs

Low-profile torque wrenches are ideal for tight access bolting jobs. They can fit into tight spaces and provide high torque for industrial bolting applications.

Low-profile torque wrenches have a slim, compact design that makes them perfect for working in tight spaces. They are ideal for use in plants, refineries, wind turbines, and other industries.

The IU-XL Series delivers superior functionality with a practical design, full-rotation swivels, inline drive, and patented 360º swivels. Its one-piece unibody construction ensures reliability and easy maintenance, making it the perfect low-profile hydraulic torque wrench.

Torque wrenches offer precise and controlled tightening of bolts, ensuring proper tension and preventing damage to equipment. They also allow for more efficient and faster bolting, saving time and labor costs.

A torque profile is a graph that shows the torque output of a hydraulic torque wrench over time. The shape of the curve illustrates the tool’s ability to maintain consistent torque throughout its cycle, providing a visual representation of its performance and accuracy.

A torque wrench typically needs recalibration after 5,000 to 10,000 uses. However, since it’s a precision tool, its accuracy can decline over time. Wear, dirt, or accidental drops can affect its performance.

Over time, torque tools can lose their calibration. This means fasteners might be too loose, coming undone under stress, or too tight, which can cause them to deform, break, or shear off.

If a torque wrench is not calibrated, its readings may be incorrect, leading to imprecise and potentially dangerous bolt tightening. This can result in equipment failure, production delays, and safety hazards.

A low-profile torque wrench is ideal for applications with limited space or restricted access, such as flange bolting, compact machinery, and offshore platforms where clearance is minimal.

Low-profile wrenches provide high torque output in tight spaces, ensuring precise bolt tightening while reducing the risk of misalignment or improper load distribution. Their slim design allows for efficient operation in confined areas, improving safety and productivity.

Unlike square drive wrenches that require additional sockets, low-profile wrenches have a direct drive mechanism, allowing them to fit directly onto nuts and bolts in tight spaces. This eliminates bulk and enhances accessibility.

These wrenches are widely used in oil and gas, power generation, heavy equipment manufacturing, and aerospace for precision bolting in high-pressure, high-temperature environments.

Key considerations include torque capacity, bolt size compatibility, space constraints, material durability, and whether hydraulic or pneumatic power is best suited for the application.