The Torq/Lite Robo-Spider is the world’s first fully-automated torquing system.

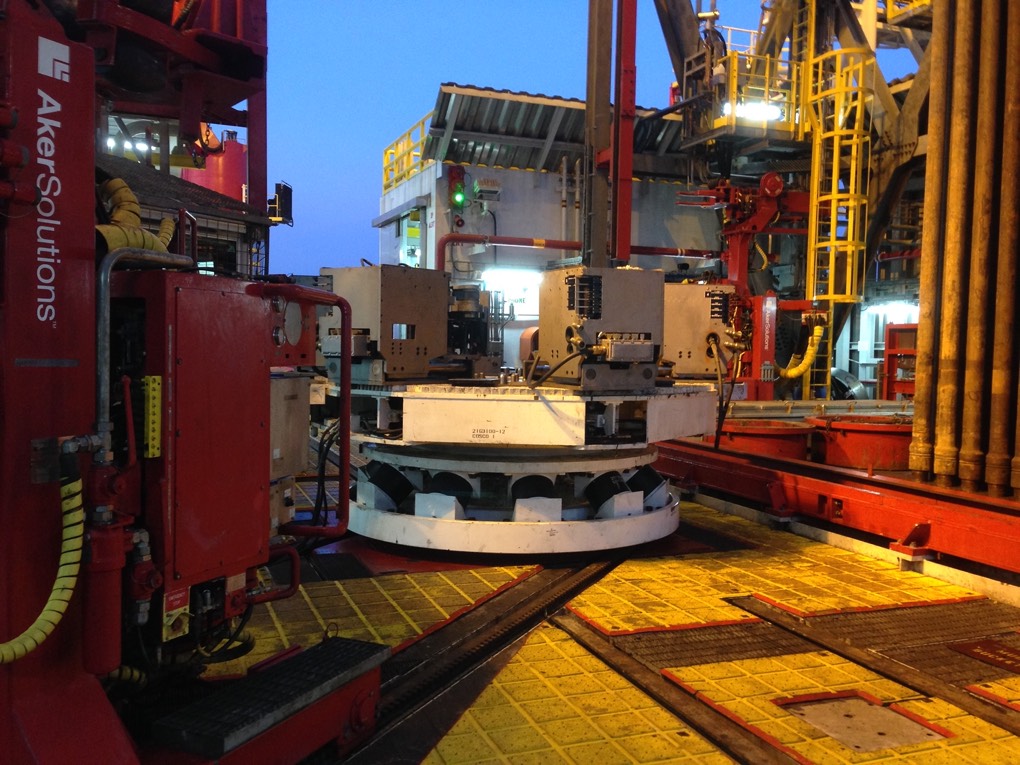

Deepwater drilling demands a safer, faster, and more accurate bolt-tightening environment. The Robo-Spider’s patented innovative and revolutionary design was developed with Cameron for the Load King series riser. It is a game changer in delivering a flawless bolt-tightening performance that significantly reduces drilling costs in daily rig operations.

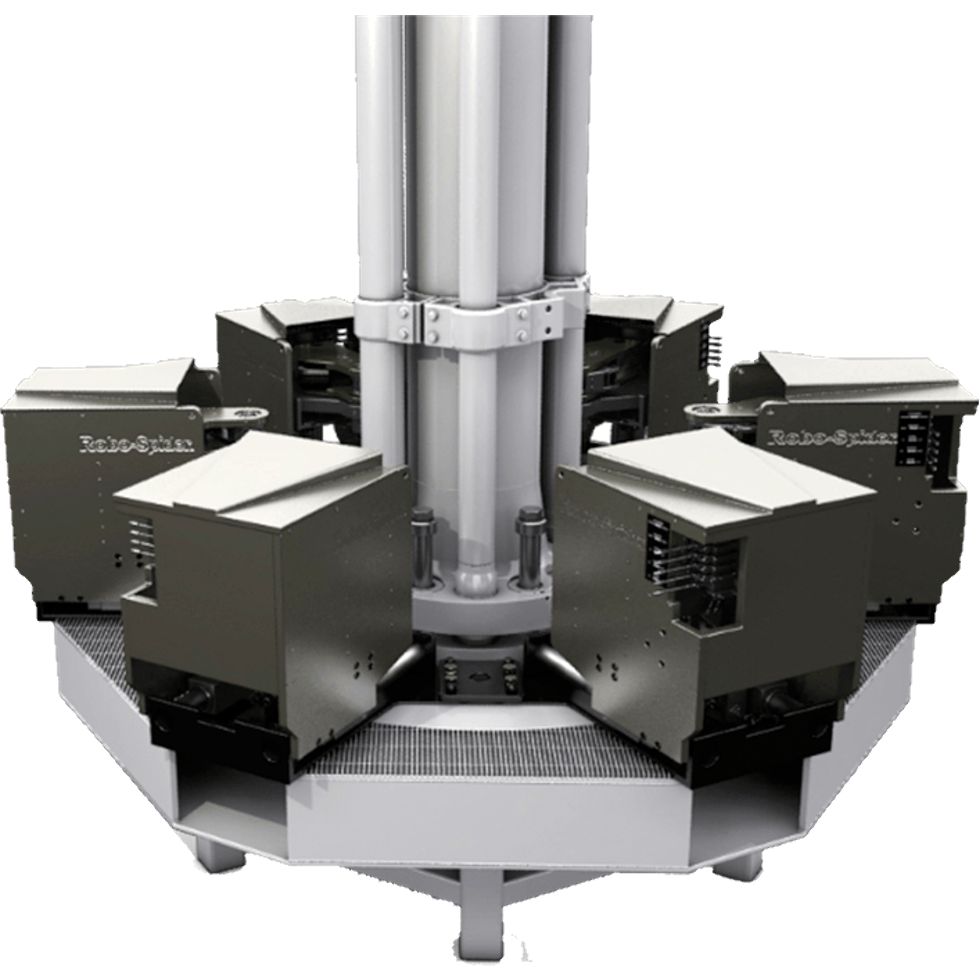

The Robo-Spider replaces a standard riser wrench tool set requiring four to six rig crew personnel to operate. Instead, it enables the operator to torque an entire riser flange of all six bolts at once with half of the personnel in the zone in one half the time, thus replacing the single riser tools that currently torque one bolt at a time.

Our wrench is versatile, durable, and all that you need to get the job done.

Robo-Spider

A revolutionary technology that reduces drilling costs and improves profitability.

The Robo-Spider is the World's first fully automated torquing system. It was designed to torque an entire riser flange at once, replacing single riser tools that do one bolt at a time. The Robo-Spider not only meets deepwater drilling demands but exceeds industry expectations, it is at the forefront of deepwater riser bolting technology.

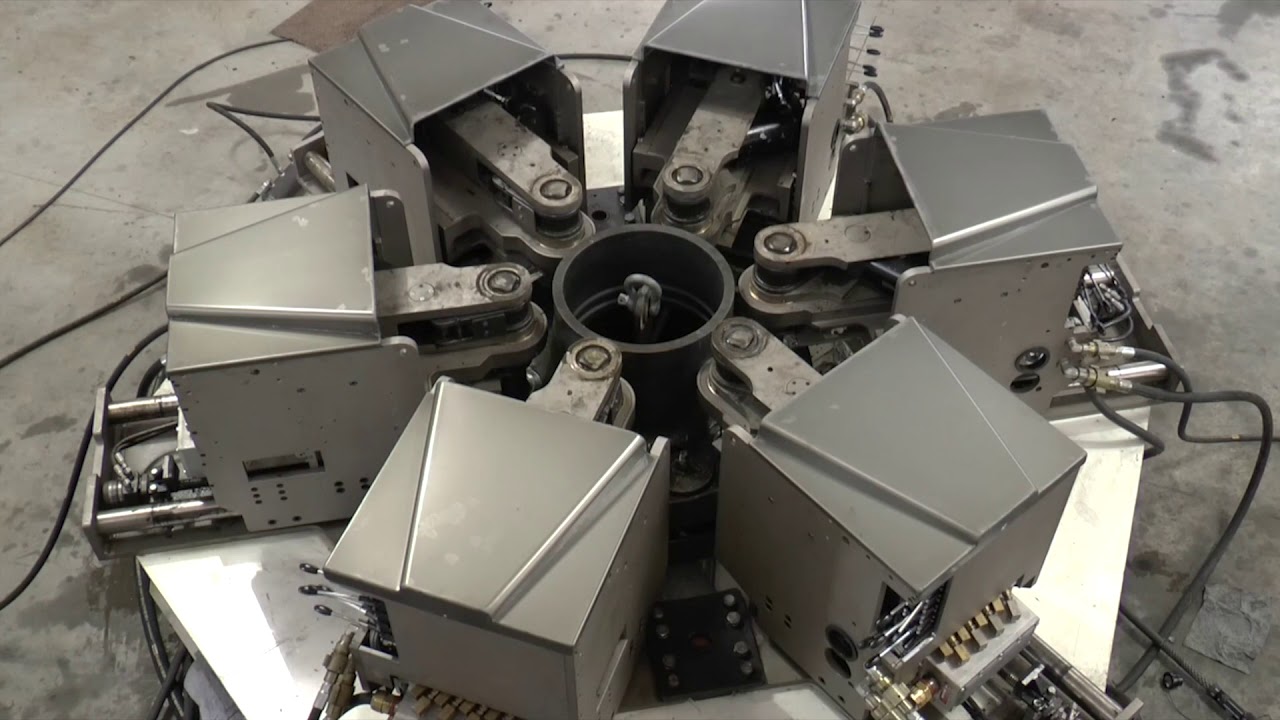

The Robo-Spider has six individual modules; each operates as a stand-alone unit, and at the same time, all the modules work in tandem to tighten each bolt with accurate and balanced preload with every turn. The Robo Spider is currently the only one of its kind available on the market and stands as the benchmark to which others try to match.

A powerful, effective pump is needed for these tools.

Product Features

Proven Technology

The design is elaborate but the core working parts are identical to the RT Series riser tools. The drive train assembly used in both has decades of patented, proven experience, and success in bolting and unbolting riser flanges.

Safe

Since the touch-screen is fully functional, you do not need the extra rig crew/techs to be anywhere near the flange during bolting, which exponentially increases the margin of safety for all involved in the riser run. You can send those rig crew/techs to complete another task.

Accurate

Once the modules have run the bolts down and shouldered them up, they wait on each other to get into the same position and the first stroke of torque is done in unison. It is a truly perfect repeatable preload.

Touch Screen

The control panel is portable, placeable, and very simple to operate. The touch-screen is easy to navigate and lets you completely control the tool with hands-free operation. There is no requirement for rig crew/techs on the spider.

Fast

Usually, there are two rig crew/techs working opposite each other on a bolted riser flange using two wrenches to work on two bolts at the same time. The Robo-Spider does all six bolts safely and simultaneously, proven to save you large amounts of time, and increase profitably by replacing human inconsistencies with unmatched, repeatable, measured performance. The average is approximately six to ten minutes between runs on each of the flanges.

Dependable

Weather conditions and rough seas mean nothing to the Robo-Spider. Hot, cold, rain, or shine, the Robo-Spider gets your riser up or down safely, effectively, and efficiently, saving you time and in return making you more profitable on each riser run performed.