Hydraulic Pumps: Key to Modern Construction Equipment

January 13, 2025

Torque Calibration Frequency: Industry Guidelines and Recommendations

February 13, 2025How to Select the Right Torque Wrench for Heavy Equipment Maintenance

Choosing the right torque wrench for heavy equipment ensures accurate torque application, prevents over-tightening or under-tightening, and minimizes the risk of expensive repairs or downtime. With so many torque wrenches on the market, selecting the right one can seem challenging.

Keep reading to learn about the different types of torque wrenches and their applications, factors to consider when choosing a torque wrench, and tips for maintaining it.

Features of Heavy-Duty Torque Wrenches

Heavy-duty torque wrenches are specifically designed to meet the demands of industrial and heavy equipment applications. Here are the key features of heavy-duty torque wrenches that make them indispensable tools:

- Adjustable Torque Range: These wrenches allow for precise torque adjustments, ensuring the correct force is applied for various components during heavy equipment maintenance.

- Durable Construction: Built from high-quality materials, heavy-duty torque wrenches can withstand extreme pressure and frequent use without compromising accuracy or reliability.

- Enhanced Leverage: Larger in size than standard wrenches, heavy-duty models provide greater leverage for applying the high torque values required in industrial settings.

- Dual Scale Readings: Many models feature dual scale readings, displaying torque values in both foot-pounds and newton-meters for added convenience and accuracy.

- Interchangeable Heads: Interchangeable head options make these wrenches versatile, allowing them to adapt to different bolt sizes and applications with ease.

- Ratcheting Mechanism: Equipped with a ratcheting system, these wrenches make operations smoother and prevent over-tightening by disengaging once the target torque is reached.

- Precision and Accuracy: Engineered for precise torque control, they minimize the risk of over- or under-tightening, which is critical for maintaining the integrity of heavy machinery.

- High Torque Output: Designed for demanding tasks, they deliver exceptional power with minimal operator effort, making them suitable for heavy-duty applications.

- Robust Durability: Heavy-duty torque wrenches are built to endure harsh industrial conditions, ensuring consistent performance and a long service life.

- Safety Features: With operator safety in mind, these tools are designed to minimize vibration and noise, reducing fatigue and lowering the risk of injury.

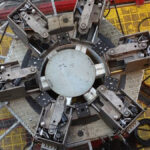

Types of Hydraulic Torque Wrenches

Hydraulic torque wrenches are typically classified into three main types: low-profile, square drive, and thin-series hydraulic torque wrenches.

Low-Profile Torque Wrenches

These wrenches are specifically designed for applications where space is restricted. Their slim, compact design allows them to fit in tight spaces with limited clearance, such as around flanges or machinery repairs. Despite their small size, low-profile torque wrenches deliver high power, making them ideal for challenging environments like pipeline maintenance or confined industrial settings.

Square Drive Torque Wrenches

Square drive wrenches feature a more traditional design with a square drive mechanism that accommodates various sockets. This versatility makes them suitable for a wide range of applications, particularly when dealing with different bolt sizes. They are commonly used in industries that require a single tool to handle multiple fastening tasks efficiently, such as construction, mining, and equipment assembly.

Thin-Series Hydraulic Torque Wrenches

Thin-series wrenches are designed for precision in applications involving smaller bolts or limited access. Their slim profile and concentric design provide exceptional strength and accuracy. These wrenches are frequently used in specialized tasks like tightening Blowout Preventer (BOP) bolts in oil refineries, where both power and precision are essential in tight operating spaces.

Choosing a Torque Wrench

Selecting the right torque wrench is essential to ensure proper clamping force, tool longevity, and safety in your operations. Here are the key factors to consider:

Bolt Material

Not all bolts are the same. Materials vary in strength and elasticity, which directly impact the torque required to achieve the desired clamping force. Choosing a wrench that aligns with the material’s properties ensures you’re applying the right pressure for optimal performance.

TorqLite’s JN Series features a patented open-gate design that lets the head latch around the nut, even when obstacles are in the way. This eliminates the need for unsafe methods to handle difficult tasks. The series can also be customized for nuts that need a special head.

Joint Design

The assembly of the joint, including the type of washer, nut, bolt, and its geometry, plays a critical role in torque distribution. Like fitting the pieces of a puzzle, every element impacts the final clamping force. Selecting a wrench that accommodates these specifics ensures proper torque application.

TorqLite’s IU-XL Series features a patented inline-ratcheting design that combines the cylinder and body into one unit. This allows you to use a single body and cylinder unit for a wider range of nut sizes. All you need to do is change the head when switching nut sizes, saving time and effort.

Load Requirements

The expected load on the joint dictates the required torque for a secure connection. Too much torque can overstress components, while too little can lead to failure. Finding the right balance is key, and the right torque wrench helps achieve that balance.

TorqLite’s TLSM Series Torque Multipliers use intelligent joint sensing technology to monitor the joint during tightening. It applies dynamic braking if needed to prevent torque overshoot caused by motor inertia.

Environmental Conditions

Temperature, lubrication, and other environmental factors can influence torque requirements. Frictional forces between the bolt and joint components can shift based on these conditions, making it essential to select a wrench suited for the specific environment to ensure reliability.

One prime example of a torque wrench that can handle tough environments is TorqLite’s SU-XL Series. This square-drive hydraulic torque wrench is designed to handle make-up and break-out tasks with precision and reliability. Known for its durability and performance, it’s commonly used in construction, mining, oil and gas, and wind energy industries.

Final Thoughts

Hydraulic torque wrenches are essential for heavy-duty applications requiring precise and accurate torque control. With various types and features available, selecting the right torque wrench for heavy equipment is crucial to ensure safe and efficient operations.

Consider the factors discussed above when choosing a torque wrench, and always prioritize quality, durability, and safety in your selection process. And if your tools require precision and reliability, TorqLite has a wide range of hydraulic torque wrenches to meet your needs. Learn how our industry-leading torque solutions can benefit your operations. Contact TorqLite today!