Tools for The Hydropower Industry: What They Are And What They Should Be

January 26, 2024

Seven Common FAQs about Industrial Torque Wrenches

July 31, 2024From Challenge to Solution: How Robo-Spider Meets Demands

In the demanding world of deepwater drilling, precision, speed, and safety are paramount. That’s why Robo-Spider was created.

Traditional methods often fall short, requiring large crews and extensive time to complete critical tasks.

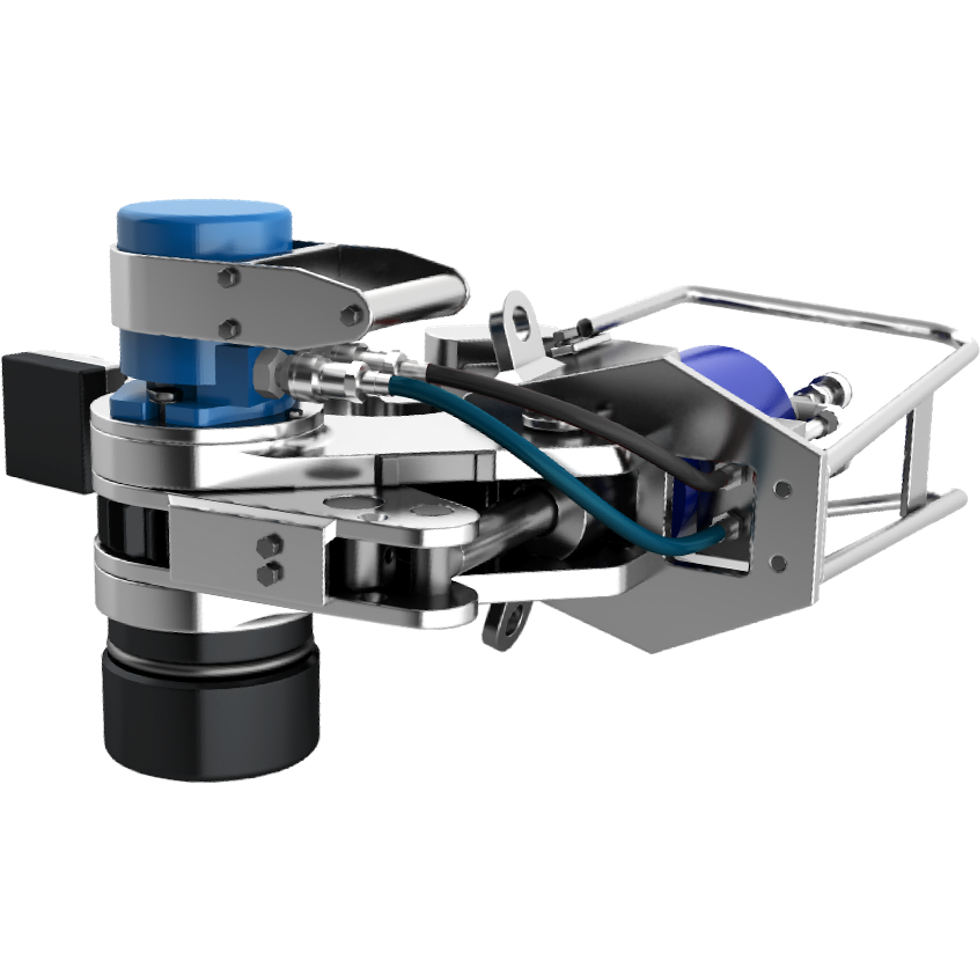

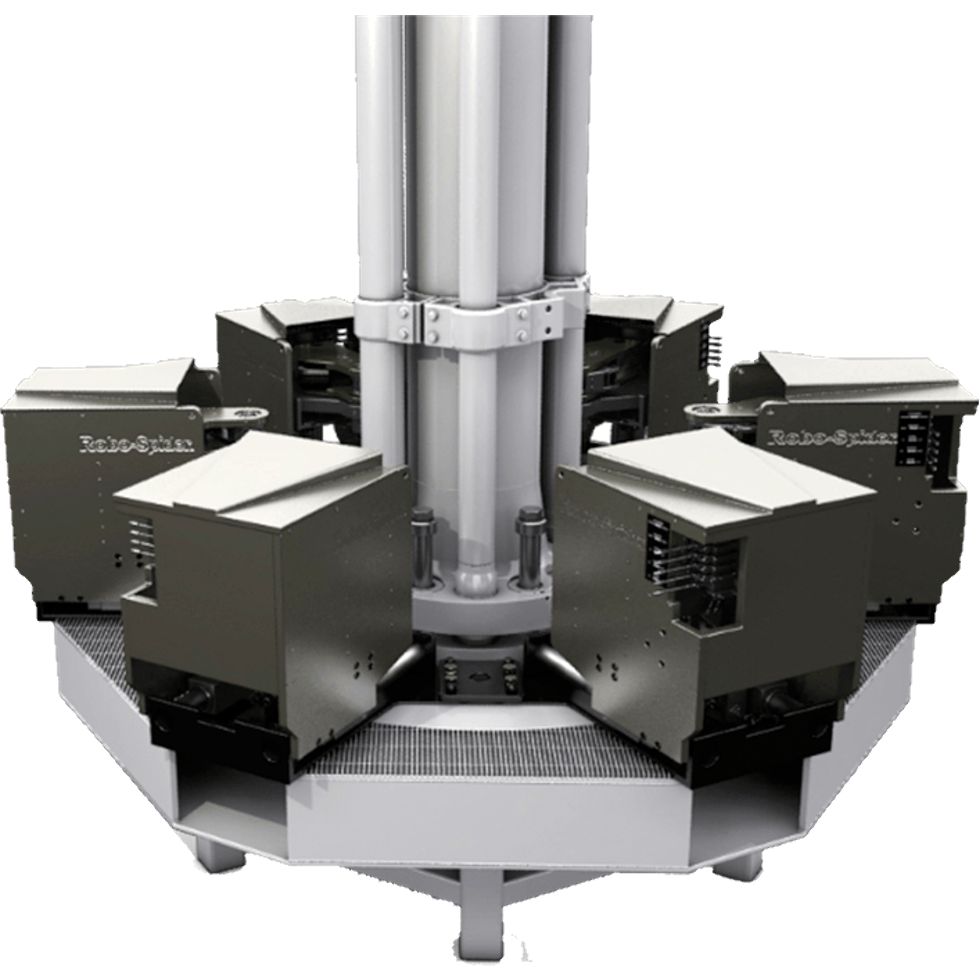

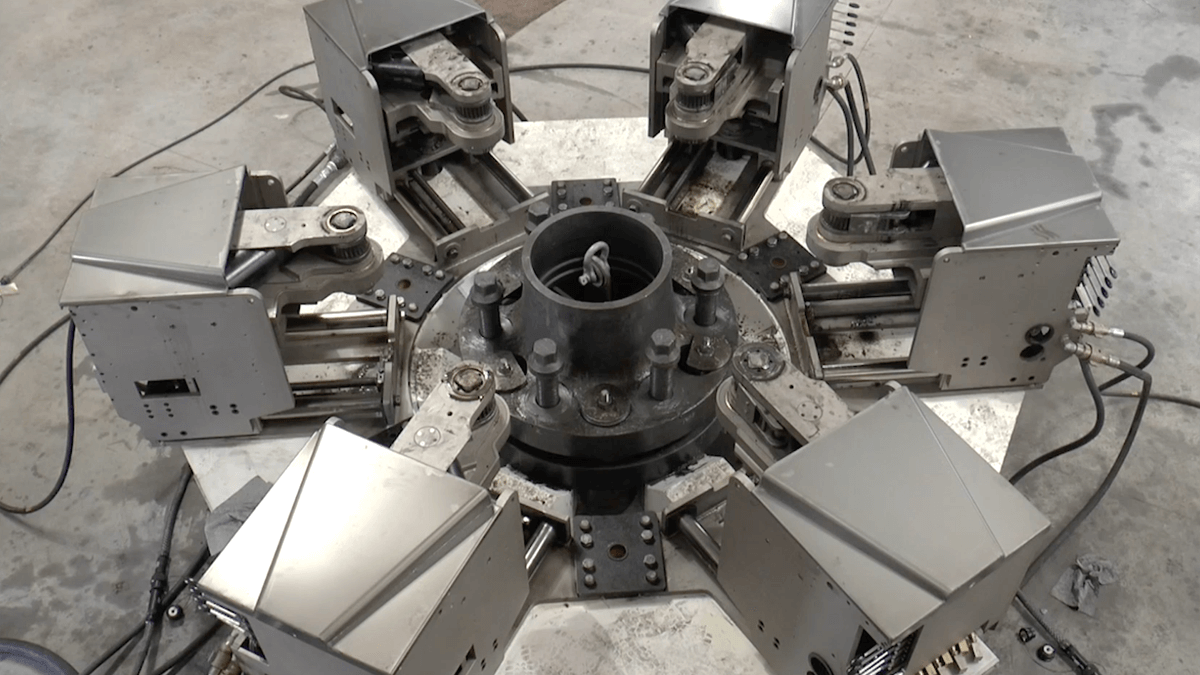

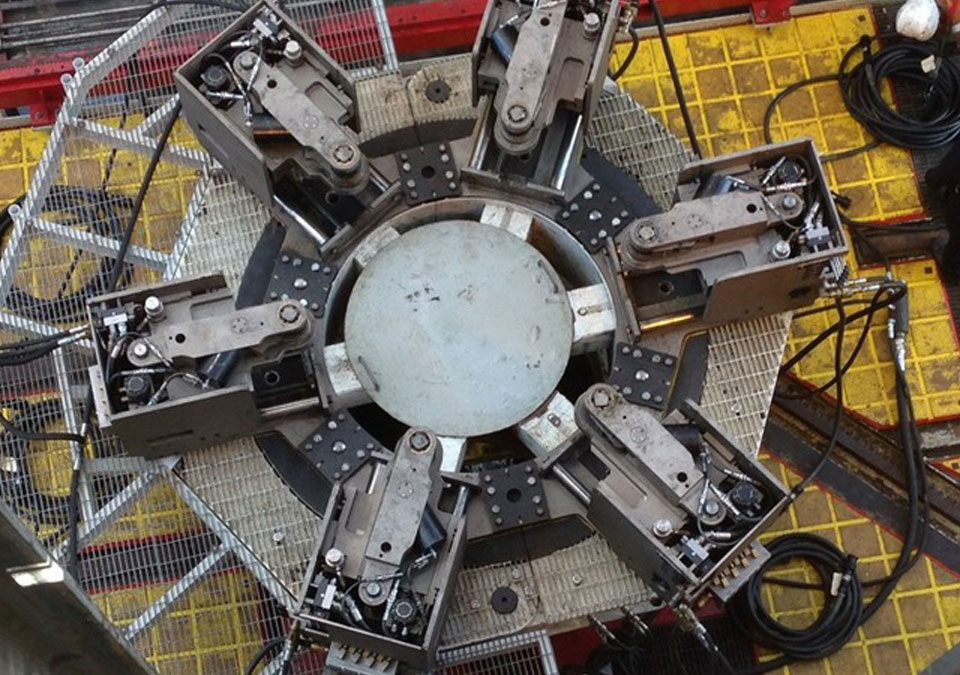

Enter the Robo-Spider – the world’s first fully-automated torquing system, designed to transform the bolt-tightening process and meet the industry’s most stringent demands.

Revolutionary Technology for Unmatched Performance

The Robo-Spider’s patented torque system, developed in collaboration with Cameron for the Load King series riser, is a game-changer.

Unlike conventional tools that require four to six crew members to operate, the Robo-Spider can torque an entire riser flange of six bolts simultaneously with just half the personnel.

This innovative approach not only reduces the manpower needed but also cuts the operation time in half.

Proven, Safe, and Accurate

One of the standout features of the Robo-Spider is its proven technology.

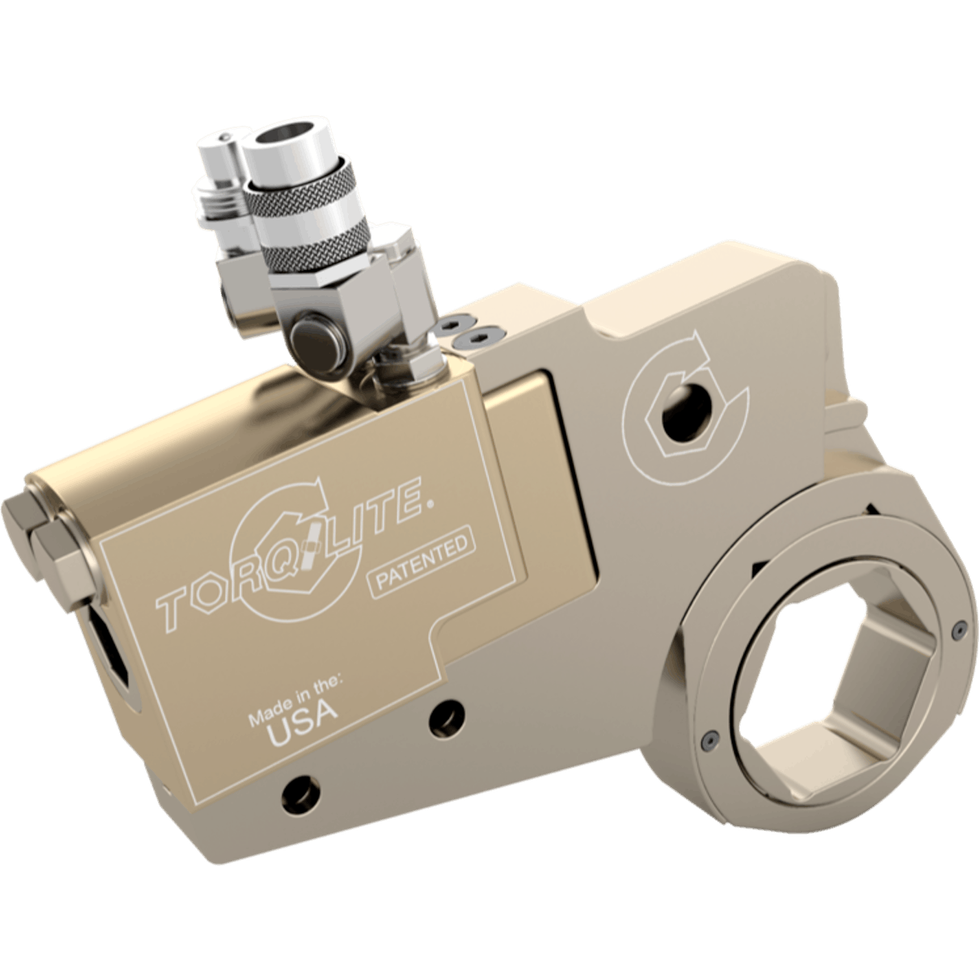

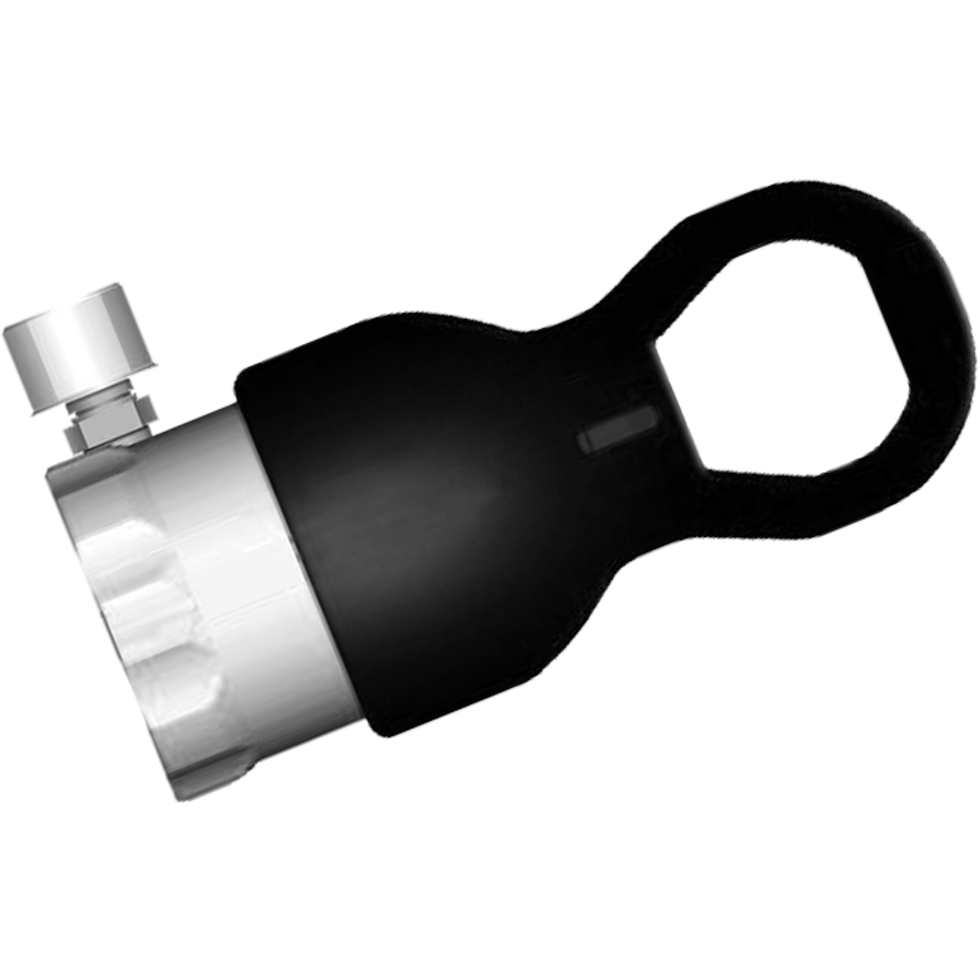

The core components are based on reliable RT Series riser tools, boasting decades of success in bolting and unbolting riser flanges. Safety is significantly enhanced, as the touch-screen controls allow for remote operation, keeping crew members away from the hazardous flange area.

The Robo-Spider’s six individual modules work in tandem to deliver precise and balanced torque.

Each module tightens its respective bolt in unison, ensuring a perfect, repeatable preload every time. This level of accuracy is essential for maintaining the integrity of the riser flange under extreme conditions.

User-Friendly and Efficient

Ease of use is another hallmark of the Robo-Spider.

The portable control panel with its intuitive touch-screen interface makes operation straightforward and hands-free. This system eliminates the need for rig crew/techs on the spider, further enhancing safety and efficiency.

Traditionally, two crew members would work opposite each other on a bolted riser flange, but the Robo-Spider streamlines this process, handling all six bolts simultaneously.

This efficiency translates into significant time savings – approximately six to ten minutes per flange – and improves profitability by replacing human inconsistencies with reliable, repeatable performance.

Dependable Under Any Condition

Weather and sea conditions often pose challenges in deepwater drilling, but the Robo-Spider is built to withstand these elements.

Whether it’s hot, cold, rainy, or stormy, it ensures your riser operations continue smoothly and safely, minimizing downtime and maximizing productivity.

The Future of Deepwater Drilling

The Robo-Spider represents the future of deepwater drilling technology.

It not only meets but exceeds industry expectations by delivering safer, faster, and more accurate bolt-tightening solutions. As the benchmark for deepwater riser bolting technology, it stands alone in its capability and reliability.

Embrace the revolution in deepwater drilling with the Robo-Spider, and experience a new era of efficiency and safety.

Ready to Transform Your Operations?

Visit TorqLite today to learn more about the Robo-Spider and how it can revolutionize your deepwater drilling projects.

Discover the benefits of our innovative technology and take the first step towards safer, faster, and more accurate bolt-tightening solutions.

Let us help you meet and exceed your operational goals.