From Challenge to Solution: How Robo-Spider Meets Demands

July 11, 2024

Boosting Industry Efficiency with Square Drive Hydraulic Wrenches

September 23, 2024Seven Common FAQs about Industrial Torque Wrenches

Are you curious about industrial torque wrenches?

Imagine you’re in the middle of an important project, and you need to ensure every bolt is tightened to the exact specification. Understanding how to use and maintain an industrial torque wrench can make all the difference in achieving precise results and prolonging the life of your tool.

Today, we’re here to answer some of the most frequently asked questions about industrial torque wrenches. Discover how these tools can enhance your projects and improve efficiency.

Keep reading to uncover expert insights that could simplify your work and optimize your wrench usage!

#1 What Is an Industrial Torque Wrench?

An industrial torque wrench is a specialized tool designed to apply a specific amount of torque to a fastener, such as a nut or bolt.

This ensures that the fastener is neither too loose nor too tight, which is crucial for the safety and integrity of mechanical systems.

#2 How Do You Use an Industrial Torque Wrench?

Using an industrial torque wrench involves setting the desired torque level on the wrench, attaching it to the fastener, and applying force until the wrench indicates the set torque has been reached.

It’s essential to follow the manufacturer’s instructions and calibrate the wrench regularly to ensure accuracy.

#3 Why Is Calibration Important?

Calibration is crucial for maintaining the accuracy of your torque wrench.

Over time and with frequent use, a torque wrench can drift out of calibration, leading to incorrect torque applications. Regular calibration checks help ensure that your wrench provides reliable and precise measurements.

#4 What Are the Different Types of Industrial Torque Wrenches?

There are several types of industrial torque wrenches, including click type, beam type, and digital torque wrenches.

Each type has its own advantages, such as ease of use, precision, and digital readouts, making them suitable for different applications and preferences.

#5 How Do You Maintain an Industrial Torque Wrench?

Proper maintenance involves regular cleaning, calibration, and storage in a protective case.

Avoid dropping the wrench or exposing it to harsh environments, and always reset the torque setting to its lowest value after use to relieve tension on the internal spring.

#6 Can You Use an Industrial Torque Wrench for All Applications?

While industrial torque wrenches are versatile, it’s important to select the appropriate wrench for each application.

Consider the torque range, type of fastener, and specific requirements of your project to ensure you choose the right tool.

#7 What Are Common Mistakes to Avoid?

Common mistakes include using a torque wrench as a breaker bar, failing to calibrate regularly, and ignoring the manufacturer’s usage guidelines.

Avoiding these mistakes can prolong the life of your wrench and ensure accurate torque applications.

Final Thoughts

Now that you’ve gained insights into industrial torque wrenches, it’s time to find the perfect tool for your specific needs. At TorqLite, we offer a comprehensive range of hand torque wrenches to meet your basic requirements. But that’s not all – we understand that different jobs demand different solutions.

That’s why we’ve expanded our inventory to include:

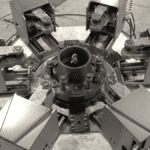

• Hydraulic torque wrenches for high-torque applications

• Electric torque wrenches for consistent, powered operation

• Battery-powered options for portability and convenience

• Pneumatic torque wrenches for rapid, repetitive tasks

• Torque multipliers for amplifying manual input

• Tensioners for specialized bolting applications

Don’t settle for anything less than perfect torque application. Contact us today at 713-983-7171 to discuss your specific requirements and let our experts guide you to the ideal solution for your job. Your project deserves the best – let’s make it happen together!