The RT Series Riser Tools are fast, safe, reliable, and extremely accurate - everything you need a riser wrench to be.

Highly Powerful Industrial Riser Wrench Tool

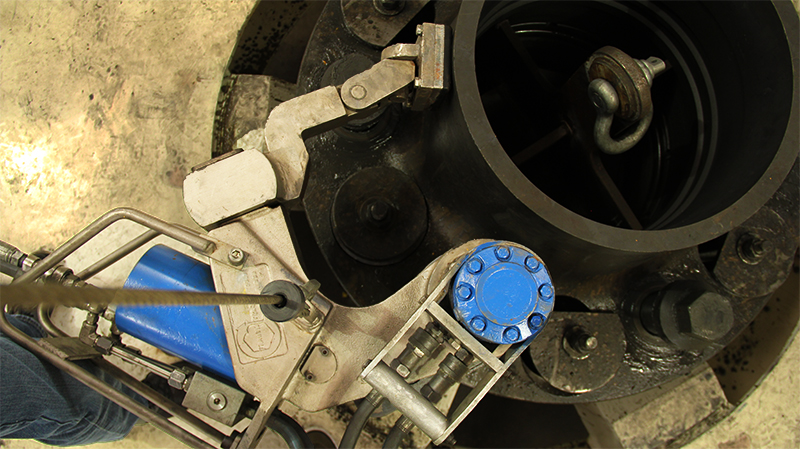

We invented the original riser tool, which took a low-efficient tool and process to create a unique solution that increased productivity and efficiency for our customers. Introduced in 1997, the RT Series industrial riser tools revolutionized bolting by delivering unmatched speed, accuracy, and protection in demanding applications. Featuring a high-speed rundown motor and a powerful cylinder, these tools streamline operations by reducing manual effort, minimizing downtime, and ensuring consistent, high-quality results.

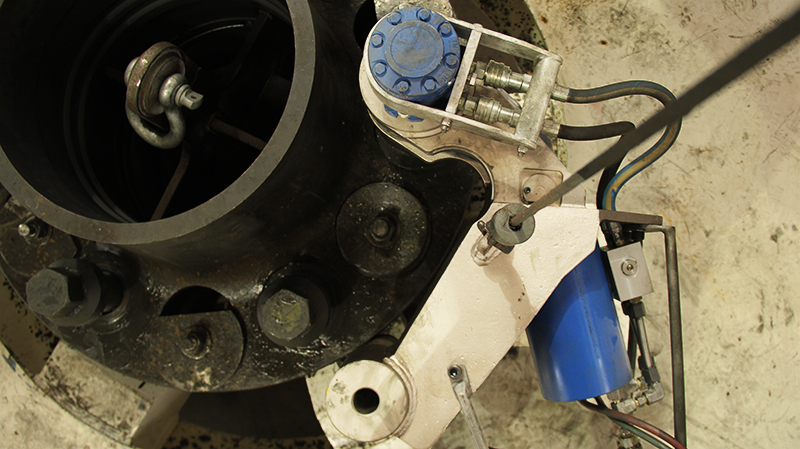

Designed for efficiency, this riser tool automatically transitions from bolt rundown to torquing without extra switches or levers. The RT series riser wrench enhances workplace safety while optimizing performance, making it the ideal choice for industries that require precision, reliability, and long-term durability.

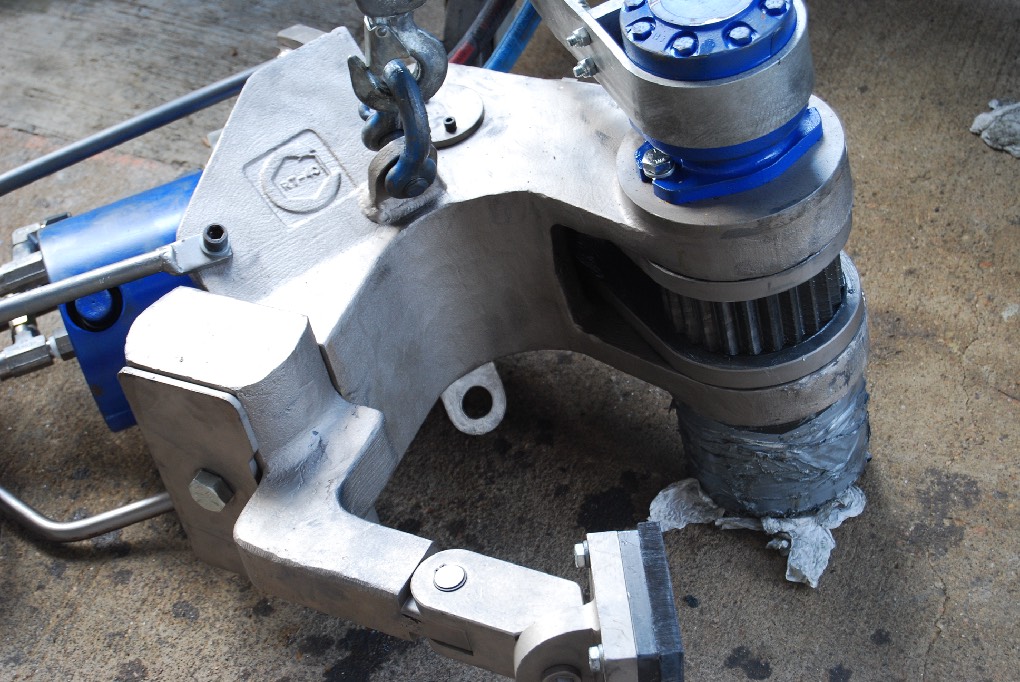

RT Series (Riser Tools)

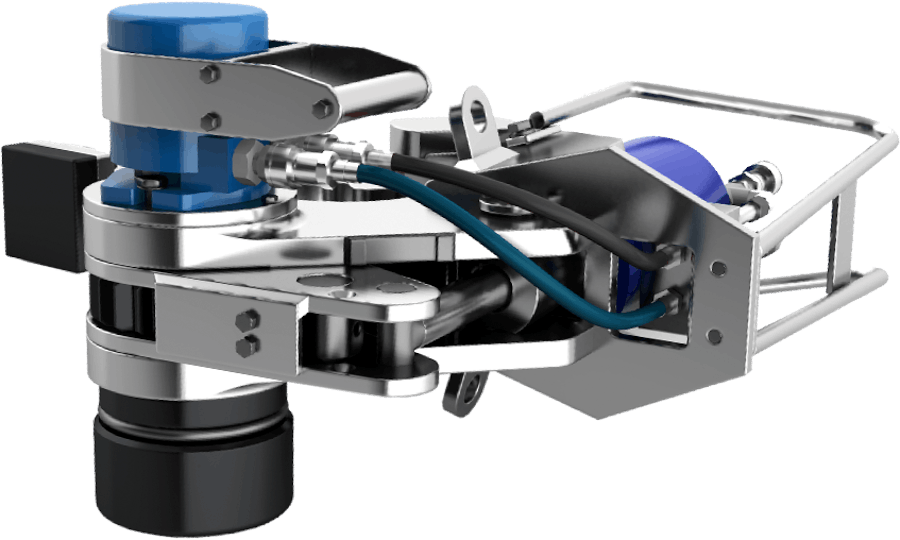

A highly powerful Industrial Riser Tool.

- Speedy Operation The RT Series operates quickly, reducing wrench time so you can complete tasks faster while saving time and money.

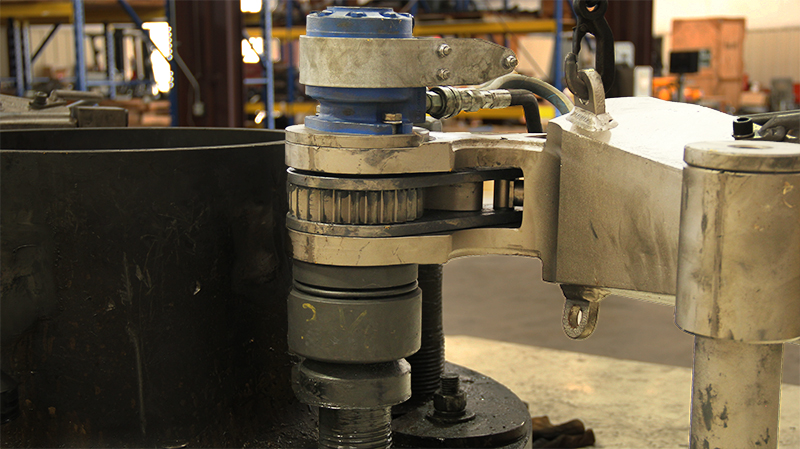

- Powerful Torque The TorqLite Riser tools securely tighten or loosen bolts, ensuring fast, safe, and dependable performance - with a maximum torque capacity of 35,968 ft./lbs.

- Practical Design Built for versatility, the RT Series features three reaction bars designed to fit different riser systems effortlessly.

Product Features

Rapid Bolting

Our industrial riser tools tighten or loosen riser bolts in seconds, helping reduce workload and minimize downtime. This faster process improves efficiency and lowers operational costs.

Adaptive Reaction Bar

The RT series includes three reaction bar systems perfectly fitting different riser types. Whatever your setup, the riser wrench adjusts to ensure a secure and reliable connection.

Powerful Torque

The RT wrench tool has a maximum torque capacity of 35,968 ft/lbs., ensuring bolts are securely tightened. It also provides a smooth, controlled process for easy bolt removal.

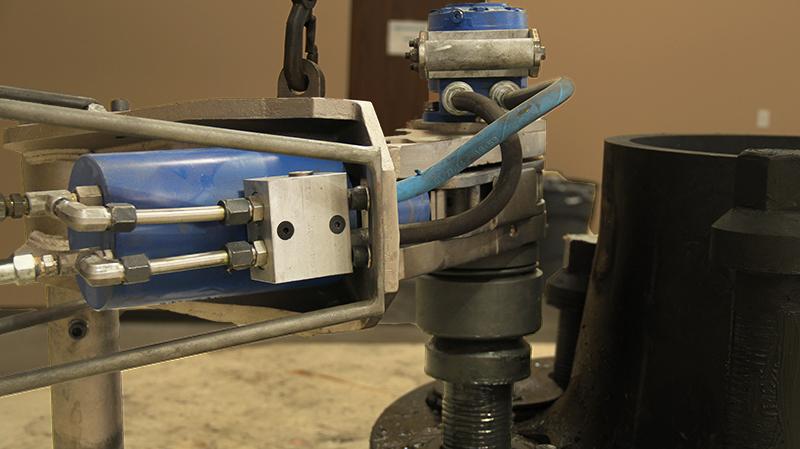

Versatile Square Drive

A 2.5-inch square drive is compatible with standard and custom impact sockets. It smoothly transitions between make-up and break-out modes, making bolting tasks more efficient.

Hands-Free Control

The RT riser wrench automatically switches from rundown to torquing mode, eliminating manual adjustments. Once set up, it operates hands-free, making it safer and simpler to use.

Complete Tool Set

Each TorqLite Riser package includes dual-control consoles, sockets, and overhead spring balancers for easier handling. The balancers reduce the tool’s weight, minimizing strain and improving usability.

Why Choose TorqLite as Your Hydraulic Bolting Provider?

Thousands of businesses have trusted TorqLite since 1981 for the highest quality torque and tensioner solutions on the market. We set the standard in hydraulic bolting, providing industry-leading riser wrenches and torque tools built for reliability and performance. With decades of engineering expertise and over 20 patented innovations, we are an ISO 9001 Certified company. Our bolting solutions consistently tackle real-world bolting challenges with precision and safety. Trusted by professionals worldwide, TorqLite ensures your bolting operations run smoothly, reducing downtime and delivering consistent, high-quality results every time.

Riser Tool Leasing Program

Our Riser Tool Leasing Program (RTLP) provides a cost-effective, worry-free solution for your rig's riser tool needs. Your lease covers all tools, equipment, labor, parts, maintenance, upgrades, customer support, and calibrations—at no extra cost. Packages are tailored to your specific rig, with standard options starting at $9,950/month. After 36 months, ownership transfers to you for free with enrollment in the Riser Tool Maintenance Program.

Enjoy free repairs, replacements, and upgrades, plus annual exchange tooling and unlimited calibrations at our Luling, LA facility. RTLP customers also receive a discounted service technician rate ($1,775/day) and 10% off all TorqLite tooling (excluding Robo-Spider).

RT Series Industrial Riser Wrench Applications

Explore Other TorqLite Hydraulic Bolting Solutions

Explore Our Quality Distributed Products

Become a TorqLite Partner or Authorized Hydraulic Tools Distributor

Want to take your business to the next level? Expand your business by partnering with TorqLite as a Warrantied Repair Service Center (WRSC) or an Authorized Hydraulic Tools Distributor.

Becoming a WRSC allows you to perform warranty repairs on TorqLite tools, giving you access to exclusive parts, training, and labor reimbursement for service work. As a distributor, you'll offer industry-leading bolting solutions, gain access to product training, and receive marketing support.

Getting started is simple—fill out the contact form, and our team will walk you through the next steps. Join our network of trusted hydraulic tool distributors today!